1. The grinding machine should be placed on a fixed and solid horizontal tabletop or table surface, thick wood is better. There are 4 screw holes in the iron plate of the lower side of the motor. Use long screws to pass through the screw holes to firmly fix the motor iron plate on the desktop or tablet (cabinet). A soft rubber pad between the motor and the table will reduce the vibration and achieve better silence.

2. The motor cover shall also be fixed on the desktop or cabinet, and shall be separated from the motor cover and the motor iron plate, and shall not be close to the iron plate to prevent the vibration and resonance between the plate and the motor cover after starting up and running, and then lock the motor cover with short screws.

3. Open the cover and fix the grinding disc on the connecting shaft. Press the grinding disc with two thumbs. Cover the cover again, tighten the lock nut, open the power supply, turn on the switch, check whether the plastic pulverizer is running in the specified direction, sound, vibration is normal, if there is abnormal noise or abnormal vibration, should shut down for inspection, troubleshooting problems until normal, to restart.

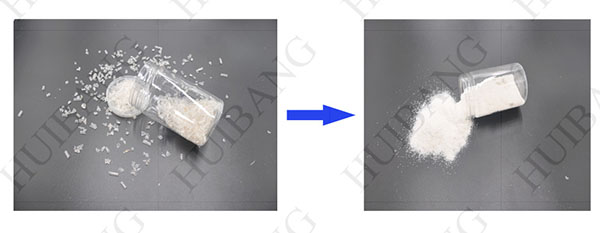

4. Start the power supply, run for about 1 minute, put the material into the hopper, screw the regulator to the appropriate position, open the cutting baffle, and make the material flow slowly into the grinding chamber. Keep the baffle small, so as not to feed too fast and jam the motor. Ordinary materials are generally ground twice, the first time using rough grinding, the second time using fine grinding.

+86-512-58639891

Telwebmaster@hb1888.com

E-mailAdd

NO.7, North of Renmin Road, Changyinsha, Zhangjiagang City, Jiangsu Province, China.